How to choose your shutter system?

1. Choice of shutter system

You have to determinate which shutter system is the most suitable for your construction according to the space available in the bodywork for its installation

1.A Front roll shutters

Manufactured with a balancer / spring assistance for smooth handling of the product, the shutters models Alu30 & Alu40 front roll models are the standard products of the manufacturer, historical and main model of the company. The shutter roll around a balancer at opening of the door (maximum surface area of 4m²).

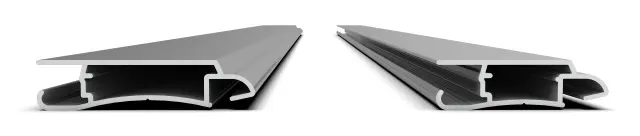

1.A1. Shutter slats height

assembled to build the door of 30 or 40mm

1.A2. Installation principle

• « STANDARD » installation :

shutter delivered in spare parts ready to assemble (assembled shutter, side tracks already drilled and machined, balancer, side panels, packet of accessories)

• « IZY » installation :

shutter delivered premounted to save time at installation (assembled shutter already installed on its side panels, side tracks already drilled and machined, packet of accessories)

1.B Top slide shutter system with balancer (with spring)

The shutter system Alu30 top slide doesn’t roll around the balancer but is deployed in a flat way into horizontal side tracks under the roof + back of the compartment if the depth is smaller than the shutter height. The shutter is linked to the balancer (equipped with a spring) thanks to cables to assist user at opening for smooth handling (maximum surface area 2m²).

1.C Top slide shutter system without balancer(no spring assistance)

The shutter system Alucoffre doesn’t roll around a balancer but is deployed in a flat way into horizontal side tracks under the roof + back of the compartment if the depth is smaller than the shutter height. This shutter model is adapted only for small dimensions which doesnt’ require spring assistance at opening because of their light weight. (maximum surface area 0.5m²).

2. COLOUR FINISH

OF THE COMPONENTS

The standard colour finish is a powder coated epoxy paint in grey RAL 7035 or white RAL 9010.

We also propose several usual RAL colour finish kept in stock or any others RAL colour following special request and quantities.

Our shutters are also available in anodised finish.

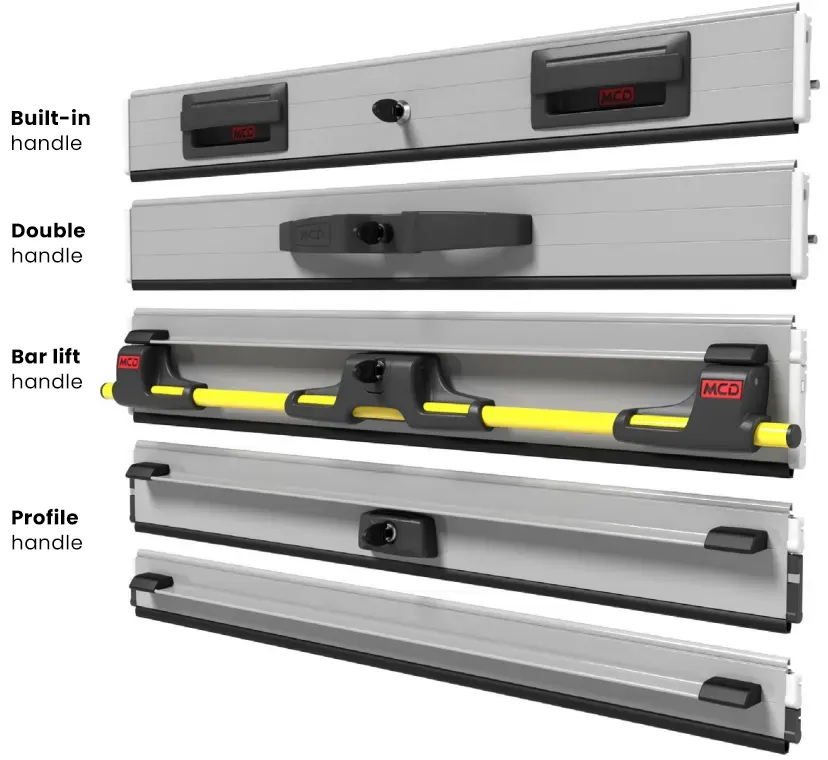

3. Closing

systems

The closing of the shutter

is done by different possibilities of handle with or without key.

It’s possible to supply the same key number for different shutters on a same order if many doors equip the same vehicle.

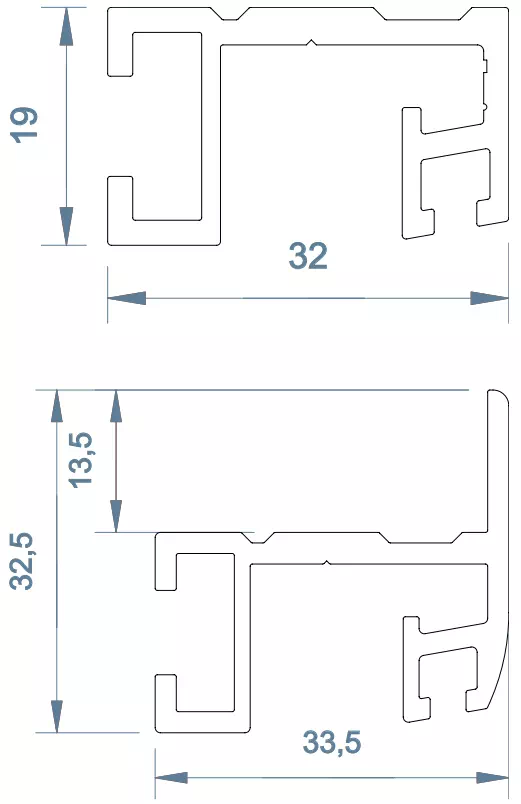

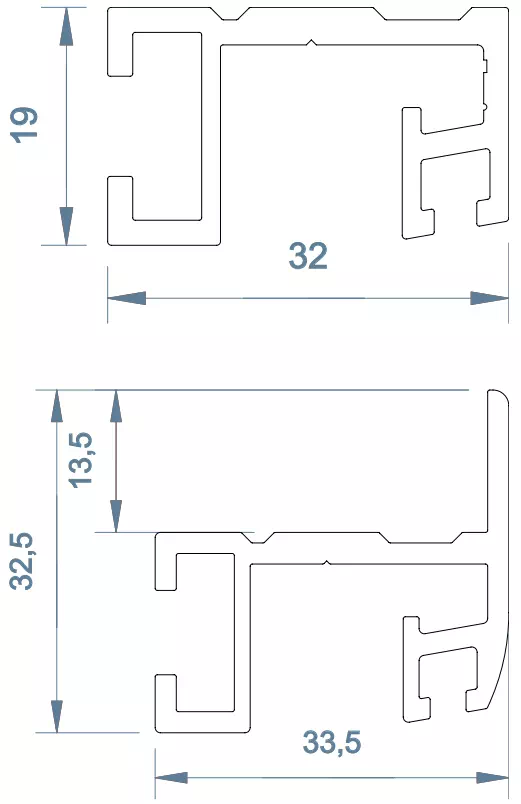

4. SIDE TRACKS MODELS

We propose 2 kind of side tracks following the bodywork possibilities :

Standard side tracks

The standard track can be installed in any bodywork configuration.

It’s a simple «U» shape in which the shutter glide.

Overlapping side tracks

The overlapping side track required a specific construction :

As the track overlap the vehicle bodywork, then it’s necessary to have a header

thickness < 9mm to let free the shutter way to go out of its tracks (see detaisl below).

5. optional

equipments

Many additionnal options are available on demand to answer each requirement :

• Bended tracks following your drawing

• Pull strap to catch the shutter handle when installed too high

• Sill plate and drip channel for a better handling of water rejects

• Sensors for automatic compartment lighting when opening the shutter

• LED Compartment lighting integrated in the side tracks or in a special

drip channel profile

• Electric locking system

• Interior unlocking

important

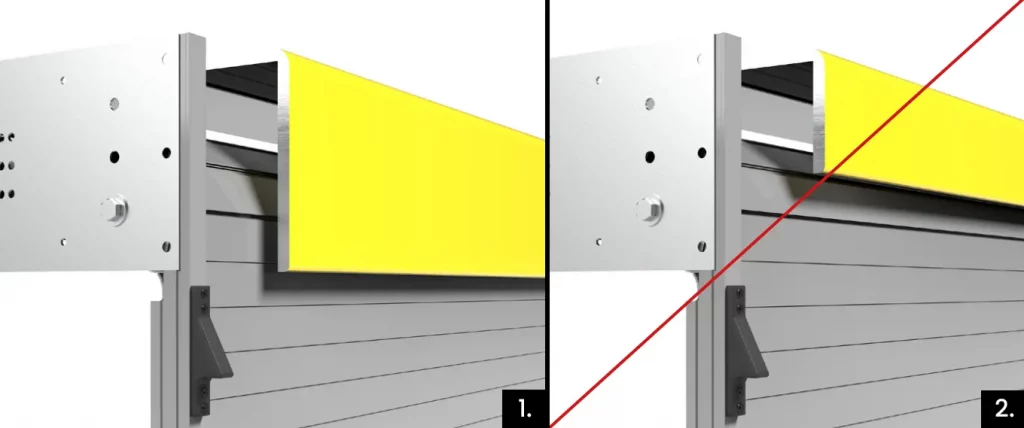

As difference from classical swing doors, a shutter required a top header panel in order to hide the rolling mechanism. The necessary header dimension is determinated following the shutter opening height, so the space required inside the comaprtment to roll the product following shutter model choice. Photo 1

Also, the articulation of the shutter’s slats in the top part shouldn’t be visible from the outisde of the vehicle. (the shutter should stay straight all along the opening). Photo 2